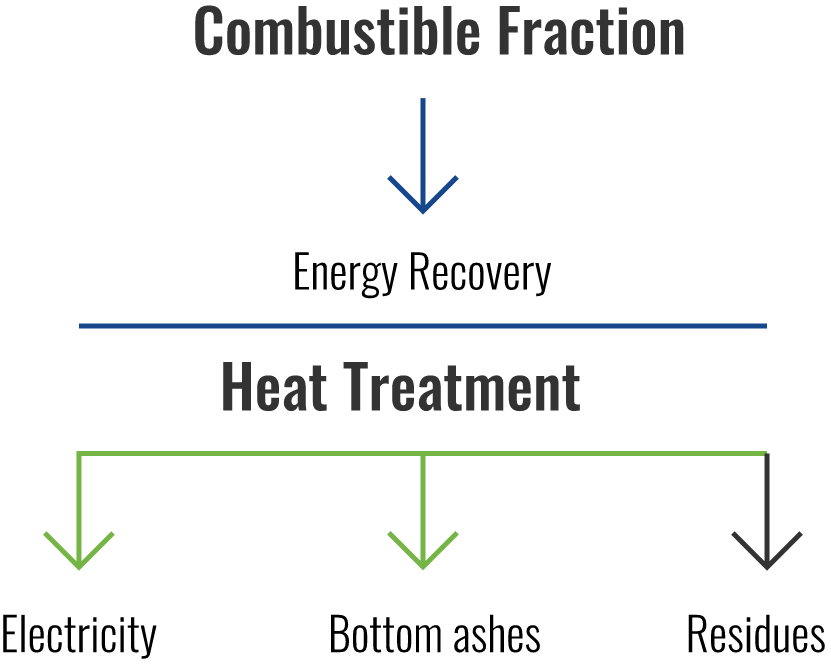

Heat treatment

Energy recovery by heat treatment consists in treating the waste inside a combustion unit, converting the heat produced by combustion to energy and treating the flue-gas. It is the same underlying principle as that of a thermal power plant: the energy generated by waste combustion is recovered and converted to steam, then to electricity. Combustion reduces waste volume by approximately 80%. The 20% remaining after combustion is called bottom ashes (used as aggregates and recovered for road construction or platform creation).

370 000 TONNES / year

of waste recovered by this unit

200 GWh / year

of electricity produced in this manner, i.e. the annual consumption of a city of 75,000 inhabitants!

Taking the process further

THE ENERGY RECOVERY UNIT CONSISTS OF FOUR ELEMENTS

- Two furnace-boiler lines,

- Turbine-generator unit for electricity production,

- Flue-gas treatment,

- Bottom ashes treatment and maturation platform.

24/7, a 4-person team, consisting of a shift manager, his/her deputy, a roundsman and a bridgeman-roundsman, oversee the proper functioning of this unit.

FURNACE-BOILERS

Both EveRé’s furnace-boilers possess a treatment capacity of 22.5 tonnes/hour.

The temperature inside the furnaces exceeds 1,000 °C. The waste stays approximately one hour inside the furnace to ensure complete combustion.

This combustion is performed exclusively using the waste and air injected into the furnaces. There is no need for any other fuel, combustion is automatically maintained by supplying waste.

The boilers, consisting of water tubes placed immediately above the furnaces, recover the heat released by waste combustion. The liquid water is converted to high-pressure and high-temperature steam (400 °C and 60 bar).

ENERGY RECOVERY

This steam produced by the boilers is sent to a 32 MW turbo-generator that converts it to electricity.

In concrete terms, the steam causes the turbine blades to rotate; this turbine in turn drives a generator, producing electrical current.

EveRé uses a fraction of the electricity it produces, thus guaranteeing its autonomy. The remainder (more than 80%) is transferred to the electrical power grid.

As it leaves the turbo-generator, the steam then passes through air condensers that cool and condense it. It thus returns to its liquid state and is conveyed towards the boilers. This circuit operates 24/7.

FLUE-GAS TREATMENT

Flue-gas treatment is one of the most important elements in terms of the environmental compliance of an energy recovery unit.

EveRé thus selected a flue-gas treatment system adapted to its requirements, using the best technologies available. The flue-gas treatment process consists of the following three steps:

- At the boiler outlet, the flue-gas are directed to a scrubber tower, used to quench acidic gasses by injecting lime milk, and also to trap dioxins and heavy metals with activated carbon.

- The fumes then pass through a deduster to remove any solid particles: : dust produced during combustion, the activated carbon used to trap the dioxins and heavy metals, along with the salts arising from acidic gas quenching with lime milk.

These particles, are recovered and sent to two silos. They are regularly removed from the site for treatment by appropriate external facilities. - At the deduster outlet, the fumes are sent to the last step in the purification process: catalytic treatment with ammonia injection o destroy nitrogen oxide molecules, along with any residual dioxins.

Before being released into the atmosphere, the quality of these flue-gas is ascertained using a series of analysers. These tests are performed on fifteen parameters and reported in real-time to the energy recovery unit control room.

A continuous dioxin sampling system is also installed; it is used for a monthly monitoring of flue-gas quality relative to this parameter.

In addition to these tests performed by EveRé, COFRAC-accredited external laboratories regularly conduct independent on-site tests using their own analysers. . Some are scheduled by EveRé, while others are unannounced, i.e. scheduled by the Government Services, without EveRé being notified of the inspection date.

All flue-gas quality results can be viewed in the “Air quality control” section. « (Only available in French on the website) ».

BOTTOM-ASHES PREPARATION FOR RECOVERY

Bottom-ashes, incombustible materials obtained at the furnace outfeed, are treated directly on-site. It first passes through a sorting chain intended to remove any coarse elements. A magnetic wheel, along with an eddy current wheel then remove any residual ferrous and non-ferrous (aluminium) materials, that are then sent to recycling.

Upon leaving this sorting chain, the bottom-ashes fine fraction then enters a maturation phase : the materials are piled up and allowed to mature. After approximately 2 months, they become an “aggregate“.

After sampling and analysis to ensure its quality, the bottom-ashes are then removed from the site for reuse in road construction or platform creation.